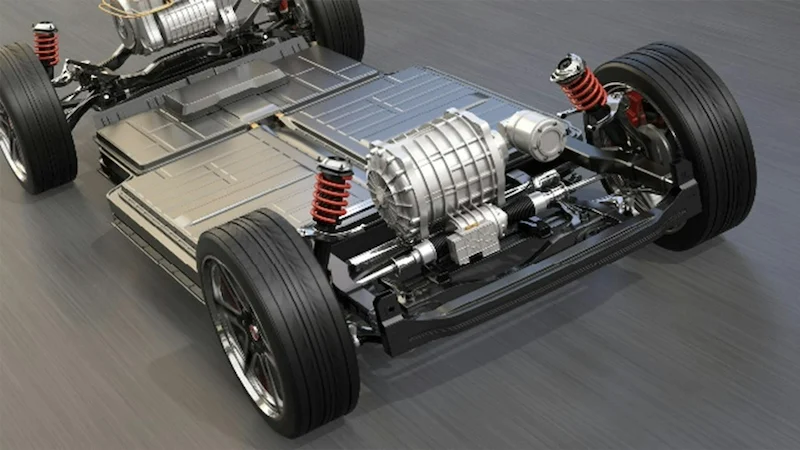

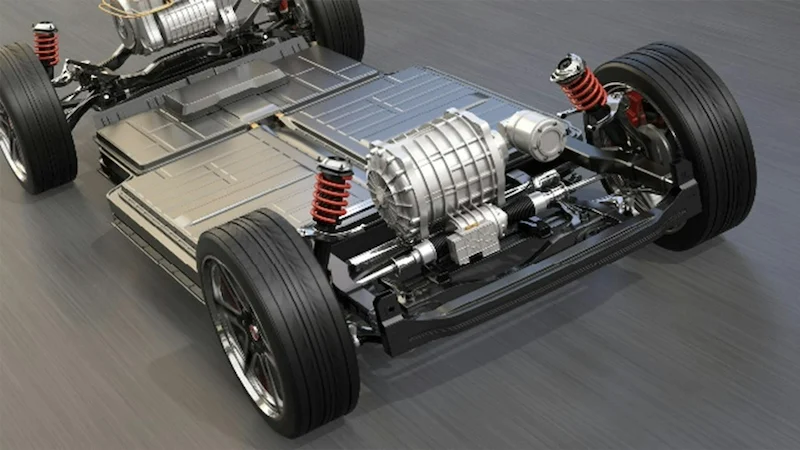

STMicroelectronics has launched its fourth generation of STPower silicon carbide (SiC) MOSFETs, designed to elevate efficiency, power density, and robustness in electric vehicle (EV) powertrains and charging circuits. These innovative MOSFETs specifically target EV traction inverters, which are vital for converting DC power from battery packs into three-phase AC to drive motors.

EV powertrain. Image used courtesy of Siemens

Available in 750-V and 1,200-V ratings, the new MOSFETs support both 400-V and 800-V battery bus voltages, significantly reducing charging times and extending driving ranges. The 750-V variants have already completed qualification, while the 1,200-V models are on track for qualification by early 2025, with commercial availability following closely behind.

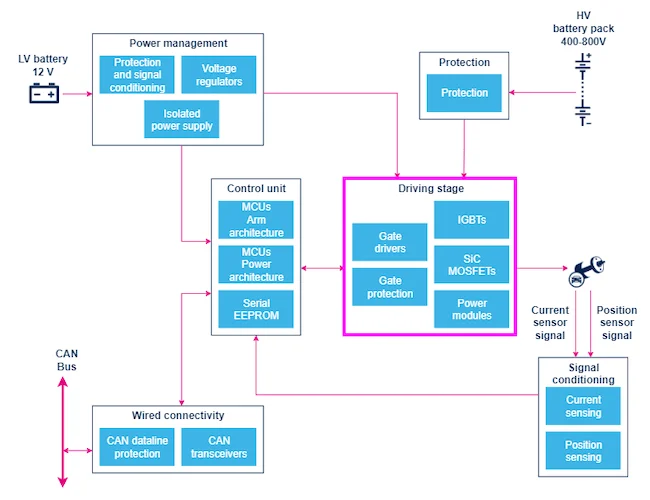

EV powertrain block diagram. Image used courtesy of STMicroelectronics

The performance of traction inverters relies heavily on the efficiency of their power components. ST's Gen 4 SiC MOSFETs boast a lower on-resistance (RDS(on)) than their predecessors, leading to reduced I2R losses and more efficient power conversion. This advancement not only enhances the overall performance of EVs but also contributes to lighter and more compact designs, addressing critical factors such as range, charge times, and costs.

Silicon carbide wafer. Image used courtesy of STMicroelectronics

With a focus on continuous innovation, ST is committed to developing new SiC solutions through 2027 and beyond. The company has invested in a vertically integrated supply chain, ensuring quality and performance at every stage of production. ST has already supplied over five million STPower SiC devices for various EV applications, reinforcing its position as a leader in the evolving e-mobility landscape.